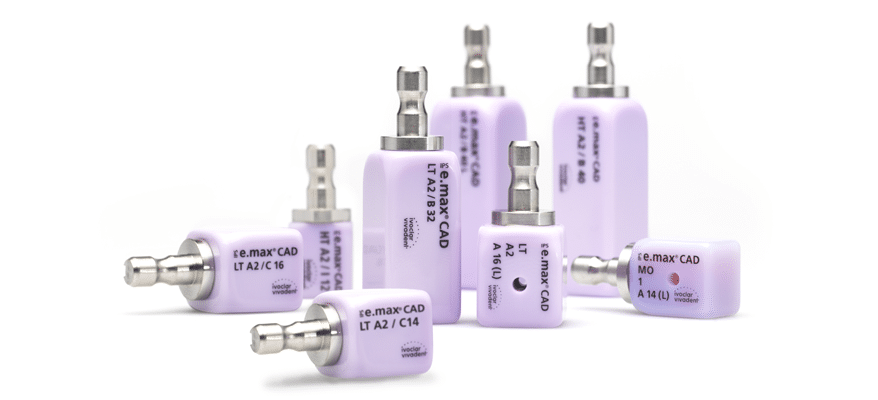

IPS e.max® CAD

IPS e.max® CAD Monolithic Solutions streamlines the fabrication of full-contour restorations that demonstrate high strength, durability and proven clinical properties.

In day to day practice, many doctors long for simplicity. Although these practitioners prefer cases such as minimal-preparation veneers, those cases don’t come along nearly as often as complicated combination cases. This is because complications often drive patients into our offices. These are the cases in which patients are embarrassed about their smile or the appearance of their teeth.

In everyday dentistry, therefore, it is important to know what to look for during examination, treatment planning and providing the patient with provisionals. Continuing education can prove vitally important to help with considerations including tissue health, tooth size and shape, and tooth position.

More important, however, is selecting a material that can span the full range of restorations the patient requires. A versatile material such as lithium disilicate is particularly appropriate for use in combination cases. Lithium disilicate glass ceramic is esthetic, demonstrates high flexural strength, and can be conventionally cemented or adhesively bonded.

For combination cases that require otherwise incompatible materials to fabricate different restorations, lithium disilicate can create full-contour restorations from one high-strength ceramic. Even more remarkable, lithium disilicate is indicated for placement in all areas of the mouth when specific considerations are accounted for. For laboratory ceramists who work closely with dentists, lithium disilicate (Ivoclar Vivadents’s IPS e.max® Press, IPS e.max® CAD) enables versatile processing with the lost-wax hot pressing technique or CAD/CAM milling.

Indications

Possibly lithium disilicate is indicated for inlays, onlays, thin veneers, veneers, partial crowns, anterior and posterior crowns, 3-unit anterior bridges, 3-unit premolar bridges, telescope primary crowns, and implant superstructures.2,3,4 When minimal tooth preparation is desired (e.g., thin veneers), the IPS e.max® lithium disilicate can be pressed to just 0.3 mm while ensuring strength of 400 MPa. When sufficient space is available (e.g., retrusion of a tooth), the teeth do not need preparation.

Indications for the CAD/CAM lithium disilicate include inlays, onlays, veneers, partial crowns, anterior and posterior crowns, telescope primary crowns, and implant superstructures. For a posterior crown fabricated to full contour using CAD methods, lithium disilicate offers 360 MPa of monolithic strength throughout the entire metal-free restoration.

IPS e.max® CAD Preparation

Click here to view the e.max® chairside preparation guide.

Closing Thoughts

Combination cases are encountered during everyday dentistry. They often require multiple restorations, using a versatile material that enables integrated, seamless fabrication of all restorations. Lithium disilicate’s beauty is its versatility. It can be pressed as thin as 0.3 mm for minimally invasive dentistry, and lab technicians can cut back and layer it for more natural-looking results.

ADA Insurance Codes

Single Unit: D2740

Bridge Abutment: D6740

Bridge Pontic: D6245

Veneer: D2962